wire edm machine working principle

1 Electric spark perforation. Wire edm machine working principle.

Cnc Wire Cut Cnc Wire Edm Wire Edm Wire Edm Machine Working Principle Youtube

Ad Upgrade The Versatility Minimize The Set-Up Time Of Your EDM.

. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. A wire cutter also known as a wire EDM is based off the same principle as a traditional EDM. It is not the most popular CNC machining.

Ad Full suite of CNC machining services including the latest in wire EDM machining. Ad At Surplex you will find used machinery and industry equipment at best prices. Be sure you will get the best out of more than 4000 used machines and tools.

A wire EDM machine can. The Five Benefits of Using a Wire EDM. Ad Full suite of CNC machining services including the latest in wire EDM machining.

Ad Full Service EDM Job Shop. Professional Wire EDM Services. Ad Faster processing times superior surface finishes for the most complex part geometries.

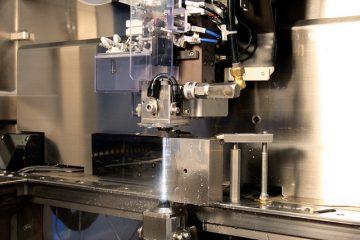

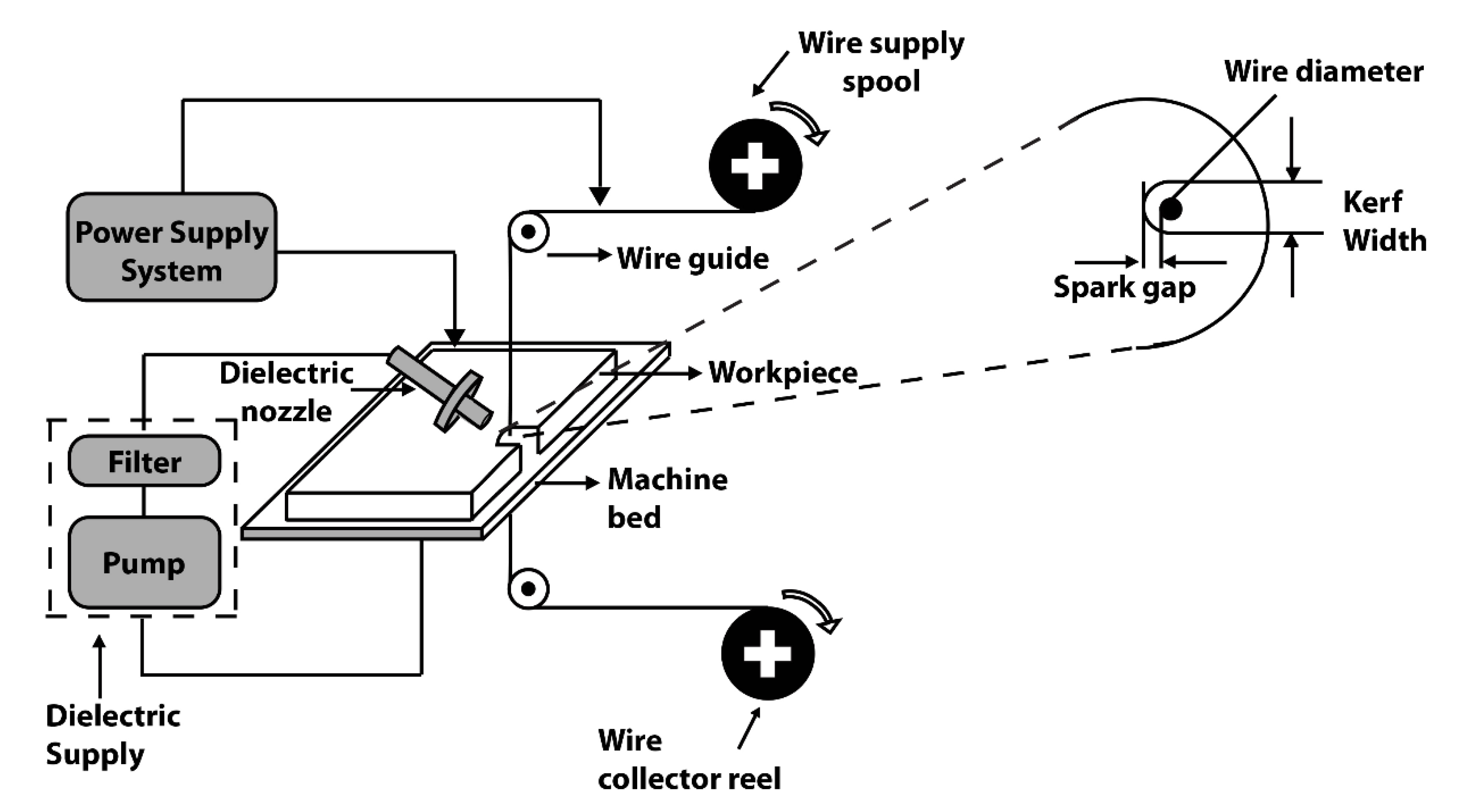

Die sinker or ram EDM. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. Electrical Discharge Machining Working Principle What is the basic principle of EDM and how the material is removed in this process.

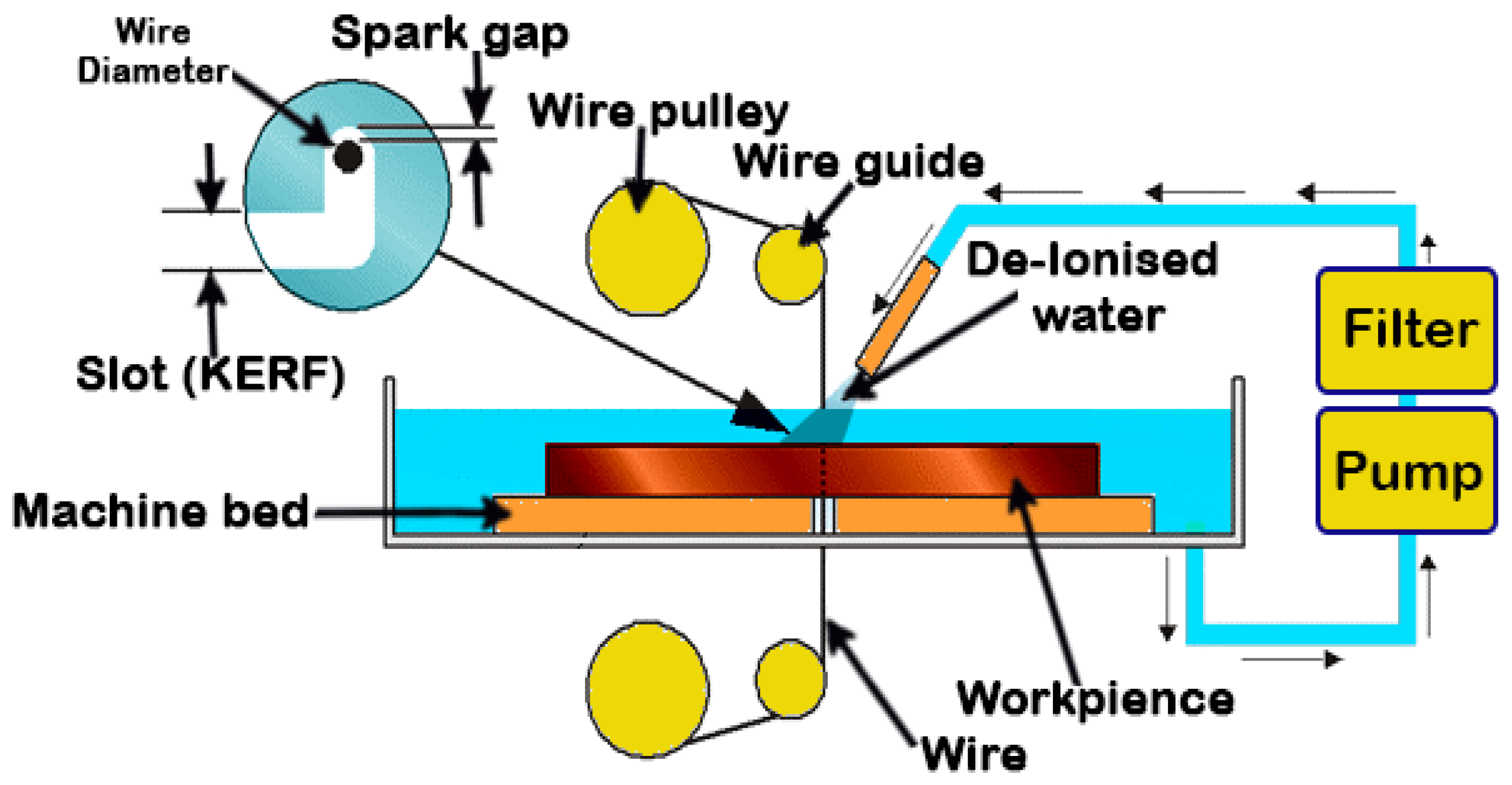

Holes in the air brakes or. Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material. For quality parts delivered on time choose Xometry cnc machining services.

Makino EDMs have a streamlined and efficient interface that helps work get done faster. This is all about electrical discharge machining principle working equipments advantages and disadvantages with its diagram. Here are some applications of Electrical Discharge Machining.

The principle behind EDM was first observed in 1770 by Joseph Priestley who was. The EDM process involves using thermal energy to remove excess material from an object creating the required shape for a task. Wire EDM which came into commercial use.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. It is used for producing hole size less than 01 mm. For quality parts delivered on time choose Xometry cnc machining services.

An EDM machine is the piece of equipment used to carry out this manufacturing process. There are many different specialised types of EDM machine but they generally fall into three separate categories. As the spark jumps across the gap material is then removed.

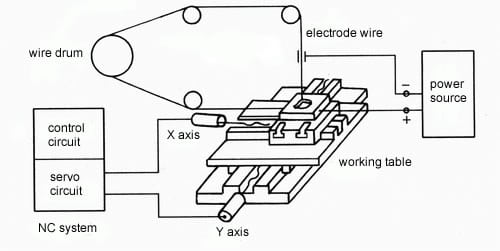

It is suitable for thermoelectric. CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo system to. Perforation machining is one of the most widely used in EDM.

It is often used to process various types of holes a round hole. Wire EDM machines can make. A major advantage of wire EDM over conventional EDM is that the continuous supply of wire minimizes the wear that occurs with a fixed electrode.

Wire filters and other consumables used on wire EDM machines. No actual contact is made between the. An EDM drill uses a tubular electrode to burn a hole through conductive material.

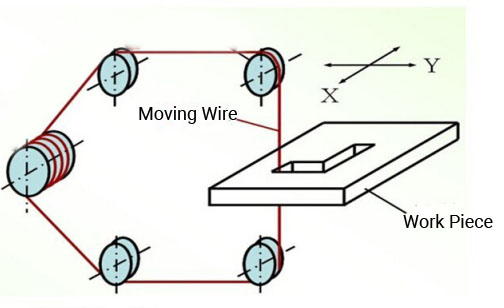

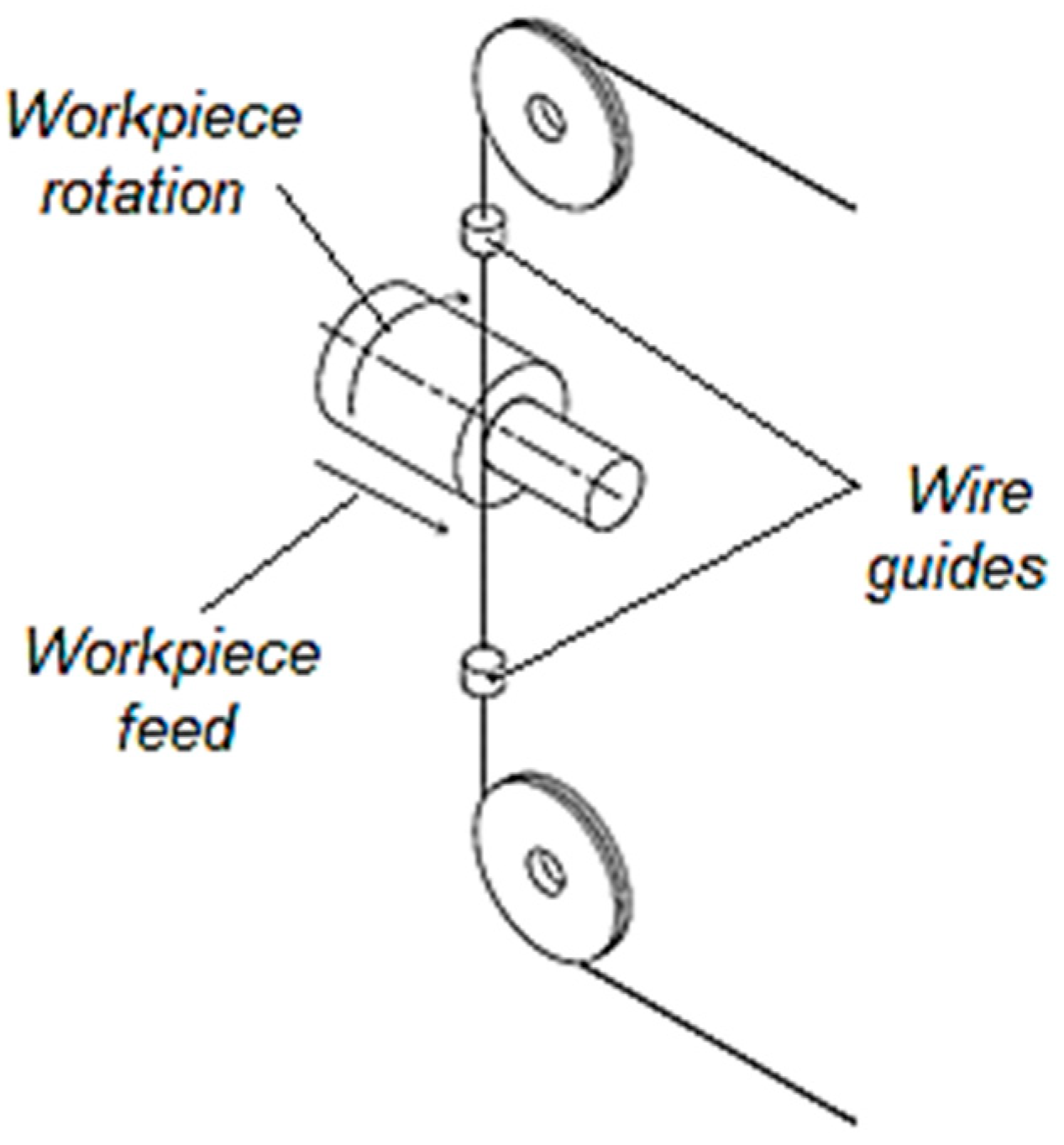

Used for die sinking or die manufacturing. Electrical discharge machining EDM is a. The basic working principle is to use a continuously moving thin metal wire called an electrode wire as an electrode to perform pulse spark discharge on the workpiece to.

As the spark jumps across the gap materia. Principle of wire cut EDM. If you have any query regarding this article.

The use of precisely focused electrical discharges makes it possible to make complex or intricate shapes and patterns. The term EDM stands for Electrical Discharge Machining. You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always.

The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting. Contact Us Today for More Information. The supply of dielectri.

Mechanical Principle 43 3q Machining Video In 2022 Steel Furniture Design Steel Furniture Mechanical Engineering Design

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Wire Electrical Discharge Machining Also Call Wedm Its Working Principle Is The Use Of Continuous Moving Thin Wire Called Electrod Cnc Sheet Metal Cnc Lathe

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

What Is Edm Machining Wire Edm 101 Sans

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

How Does Wire Cutting Work Dienamics

Materials Free Full Text Advanced Electric Discharge Machining Of Stainless Steels Assessment Of The State Of The Art Gaps And Future Prospect Html

Mas 865 How To Make Something That Makes Almost Anything

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Jmmp Free Full Text Response Surface Methodology And Artificial Neural Network Based Models For Predicting Performance Of Wire Electrical Discharge Machining Of Inconel 718 Alloy Html

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

What Is Wire Edm Electrical Discharge Machining Xact

Wire Electrical Discharge Machining An Overview Sciencedirect Topics